RFID integration CK-TP2 RFID Inventory Management Tunnel System

When batch scanning has to keep up with real warehouse speed

If you’ve ever stood next to a busy warehouse conveyor line, you know this already:

manual scanning doesn’t fail because people are careless — it fails because the pace is simply too fast.

Boxes keep moving.

Carts don’t stop.

Production lines don’t wait for inventory checks.

That’s the environment CK-TP2 was built for.

The CK-TP2 RFID Inventory Management Tunnel System isn’t a demo device or a “nice-to-have” add-on.

It’s designed for high-throughput warehouses and logistics lines where batch verification has to happen automatically, without slowing anything down.

Items pass through once — inventory is already counted

The working logic of CK-TP2 is straightforward.

Goods move through the tunnel.

No pause. No alignment. No manual trigger.

Within that short moment, the system completes a full batch read:

- Over 400 RFID tags read per second

- Entire cartons, totes, or batches captured at once

- Tag order doesn’t matter, density doesn’t matter

This is where RFID tunnel systems really show their value — especially in:

- Apparel warehouses

- Wine and spirits distribution centers

- Electronics manufacturing and assembly lines

Inventory checking stops being a separate task.

It becomes part of the physical flow.

Anti-collision performance is what makes or breaks this kind of system

In real warehouses, tags don’t behave politely.

They overlap.

They stack.

They move fast.

CK-TP2 complies with ISO 18000-6C (EPC Gen2) and is designed specifically for high-density tag environments.

In practice, that means:

- Dense batches don’t cause missed reads

- Multiple items pass simultaneously without confusion

- High-speed movement doesn’t break data integrity

If you’ve ever tested RFID equipment that looked good on paper but fell apart under load, you’ll immediately recognize why this matters.

A conveyor system that’s actually warehouse-ready

CK-TP2 isn’t just about reading tags.

It’s built to handle real goods.

- Modular conveyor structure

- Supports loads of up to 80 kg

- Suitable for cartons, bins, and transport containers

The system fits into existing logistics lines instead of forcing workflow changes.

That’s usually the difference between a pilot project and something that actually gets deployed.

A practical upgrade path for traditional warehouse cabinet and equipment manufacturers

This part is important for manufacturers already producing traditional warehouse cabinets or storage equipment.

Most of you already have:

- Proven mechanical designs

- Reliable load-bearing structures

- Clear understanding of warehouse use cases

What’s usually missing is real-time visibility.

The upgrade path doesn’t require starting over

- Keep your existing cabinet or storage structure

- Integrate Cykeo RFID antennas and RFID readers

- Connect through standard interfaces

The cabinet remains yours.

What changes is that it no longer just stores items — it knows what’s inside.

For manufacturers, this approach means:

- Minimal redesign cost

- Shorter development cycles

- A clear step into RFID-enabled warehouse equipment

You’re not replacing products.

You’re extending their capability.

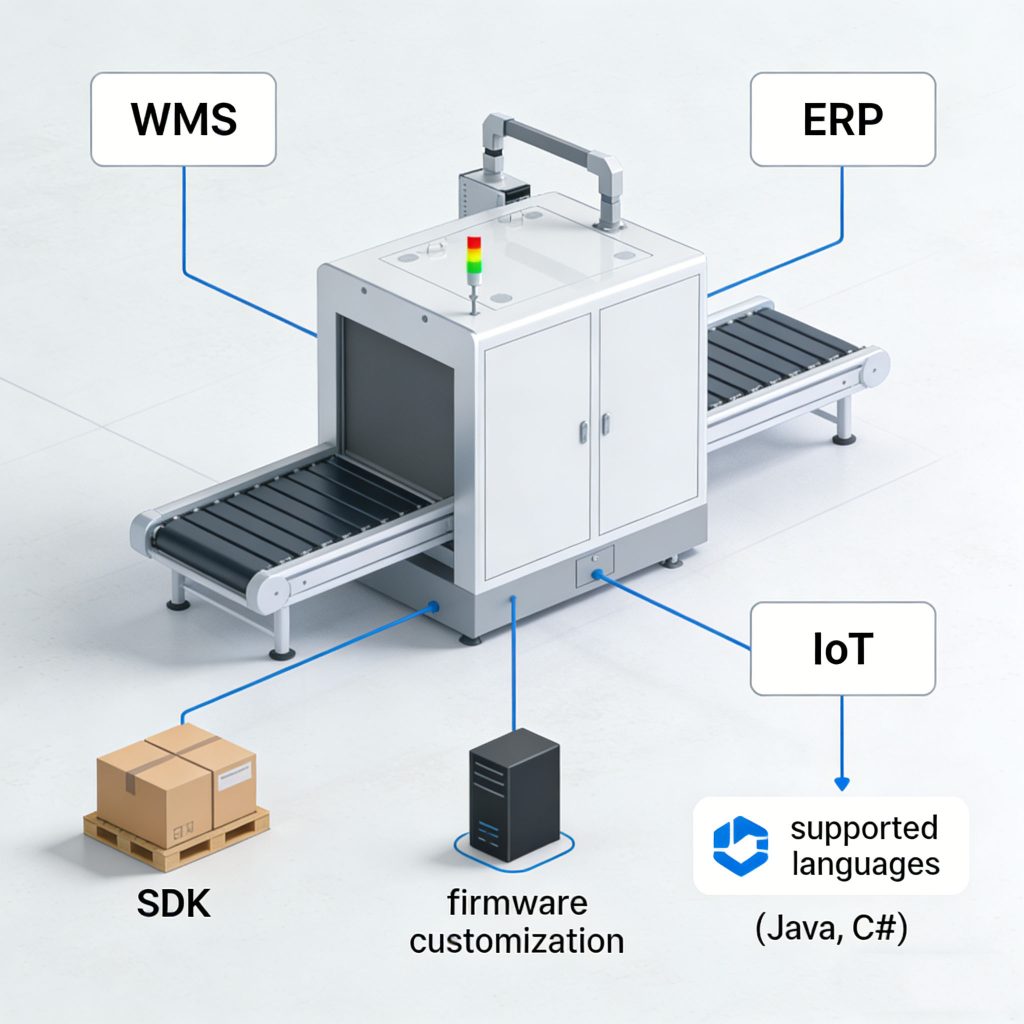

Built for RFID warehouse system providers and developers

Many RFID software providers and system integrators face the same problem:

hardware that’s difficult to integrate, unstable, or completely closed.

CK-TP2 is designed as an open, system-ready hardware node.

Integration and development support includes:

API Interfaces

- RESTful APIs

- Native APIs

- Designed for WMS, ERP, and IoT platform integration

Secondary Development SDK

- Event listening for batch reads

- Custom verification logic

- Full toolkit for firmware and application development

Supported Languages

- Java

- C#

- Cross-platform compatibility

You focus on business logic, workflows, and data models.

We make sure the physical read layer is accurate and reliable.

This isn’t just faster reading — it’s a different way of thinking about inventory

The value of CK-TP2 isn’t just “400+ tags per second.”

It changes how inventory works:

- Batch verification happens automatically

- Logistics flow isn’t interrupted

- Inventory status updates in real time, not after the fact

For busy warehouses, traditional equipment manufacturers, and RFID system providers alike,

automated batch identification isn’t optional anymore — it’s becoming standard.

CK-TP2 simply makes that transition practical.

评论

发表评论