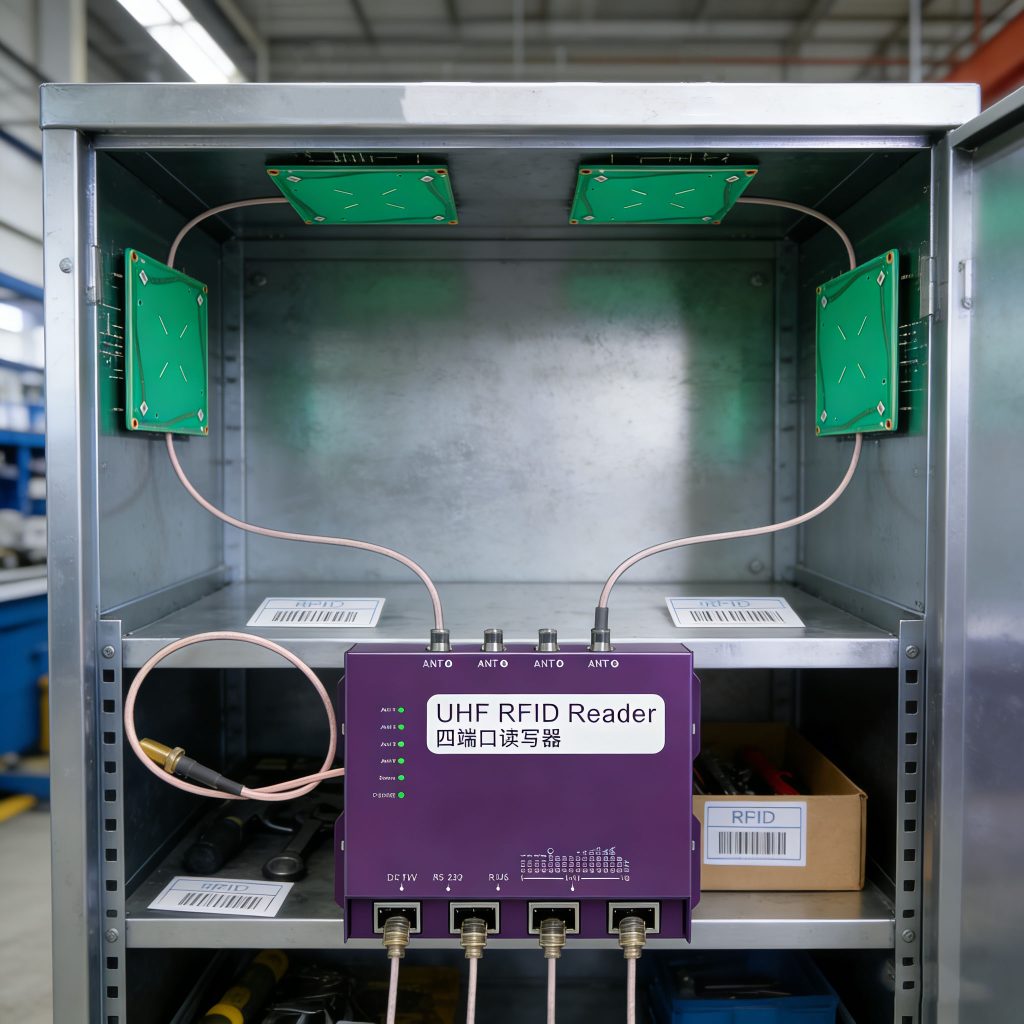

Case Study:Integrating 4-Port UHF RFID Fixed Reader into an Existing Asset Control System

Project Background

This project didn’t start as an RFID project.

The client already had:

- Traditional metal cabinets

- A working access control system

- An internal inventory platform tied to ERP

What they didn’t have was real-time visibility.

Assets were checked in and out, but reconciliation happened later. Sometimes much later.

The requirement was simple to say, harder to do:

“Add RFID tracking without replacing what already works.”

That constraint shaped every technical decision.

Why Fixed 4-Port Reader Made More Sense Than Multiple Devices

Space inside the cabinets was limited.

Running four separate readers would have been a wiring and maintenance nightmare.

The 4-port UHF RFID fixed reader solved that cleanly:

- One reader

- Four TNC antenna ports

- Independent coverage zones inside the cabinet

Each antenna was assigned to a logical area in software.

From the system’s perspective, it looked like four readers — without four power supplies, four IPs, or four failure points.

That alone simplified deployment more than expected.

Read Speed Wasn’t About Numbers, It Was About User Behavior

On paper, 600+ tags per second sounds impressive.

In practice, the value showed up when:

- A door opened and 100+ tagged items were suddenly exposed

- Technicians moved fast and didn’t pause for scans

- Drawers slid open and closed in under two seconds

Using the R2000 chipset meant the reader kept up with reality.

No buffering tricks.

No artificial delays to “let RFID catch up.”

That made the software logic simpler.

Which made the system more reliable.

Integrating into Existing Cabinets (Without Rebuilding Them)

The cabinets were steel. Thick steel.

Instead of redesigning hardware, we:

- Embedded UHF antennas inside the cabinet frame

- Tuned antenna power per port

- Used the reader’s flexible RF control to manage reflections

The reader’s IP67 industrial enclosure also mattered more than expected.

Some cabinets were installed near shop-floor environments. Dust happens. Temperature swings happen.

Once installed, the reader needed no babysitting.

API-Driven Integration Into the Client’s Platform

The client’s IT team was clear:

“We don’t want a standalone RFID system.”

So the reader was treated as a data source, not a UI device.

Integration Stack

- RESTful API for event-based reads

- Native API for tighter control over antenna behavior

- Direct connection into the client’s ERP logic

Every tag read became:

- A timestamped event

- Tied to a cabinet ID

- Associated with user access records

No middleware gymnastics.

No proprietary lock-in.

Java and C# SDKs Saved Real Time

The internal platform was already built in C#, with some services in Java.

That mattered.

Using the provided SDKs:

- Existing authentication logic was reused

- RFID events dropped directly into existing services

- No custom protocol parsing was needed

This shortened integration time significantly.

Not weeks. Days.

Secondary Development: Where the Reader Proved Its Value

The real test came later.

After the initial rollout, the client asked for:

- Different read behavior per cabinet type

- Custom alarm logic for missing assets

- Firmware-level tuning for specific asset densities

The secondary development SDK made this realistic.

We adjusted:

- Antenna duty cycles

- Power levels per port

- Read filtering logic at the firmware layer

No hacks.

No unsupported changes.

That flexibility extended the system instead of forcing a redesign.

Expanding Beyond Cabinets: Doors, Inventory, and Payment

Once the cabinet system stabilized, the same reader was reused in:

- RFID-enabled access control doors

- Fixed inventory checkpoints

- A pilot RFID-based internal payment workflow

Same hardware.

Different software logic.

That reuse lowered total system cost and simplified support.

One reader model. One API surface. Multiple applications.

Final Outcome

The client didn’t get “an RFID system.”

They got:

- Real-time asset visibility

- Fewer reconciliation errors

- A platform they could extend without calling vendors every time

From an integrator’s perspective, the biggest win was this:

The hardware didn’t limit the system design.

And that’s rare.

评论

发表评论