Cykeo CK-M1LX1 UHF Embedded RFID Module: Built for Developers, Practical for Hardware Buyers

When RFID projects fail or drag on, it’s rarely because the read range wasn’t long enough.

Most of the time, the real problems show up later — messy integration, unclear APIs, unstable behavior in real environments, or hardware that’s painful to deploy at scale.

That’s exactly where the Cykeo CK-M1LX1 UHF Embedded RFID module stands out.

It’s not just about RF specs. It’s a module designed to work with software teams, while still checking all the boxes hardware buyers care about.

1. Why CK-M1LX1 Works Well for Software Developers

From a developer’s perspective, an RFID module is only useful if it fits cleanly into an existing system. CK-M1LX1 focuses heavily on that layer.

Clean, Standardized APIs

CK-M1LX1 provides well-structured APIs and SDK support for Java and C#, which already covers a large percentage of enterprise and industrial systems. You’re not forced to reverse-engineer low-level protocols just to read a tag.

Typical operations — inventory scans, EPC reads, write commands, RF power control, filtering — are exposed in a way that feels predictable and scriptable. That makes it easier to integrate into WMS, MES, ERP, or custom IoT platforms without extra glue code.

SDKs That Actually Save Time

Cykeo doesn’t stop at API definitions. The SDK includes:

- Sample projects

- Reference code

- Clear command structures for common RFID workflows

For developers, this means less trial-and-error and fewer “why does this command behave differently today?” moments during testing.

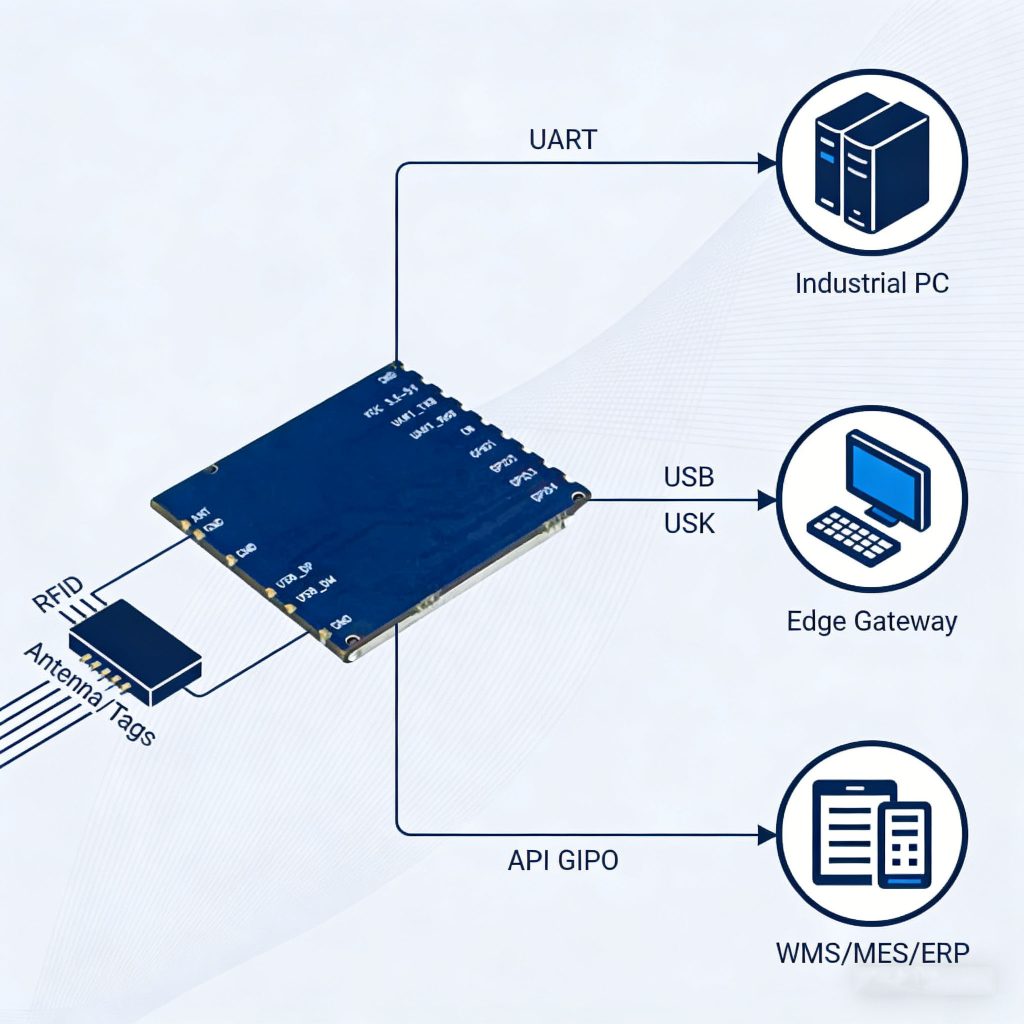

Flexible Communication Interfaces

The 15-pin port supports UART, USB, and GPIO, which gives developers and system architects flexibility when choosing controllers or gateways. Whether you’re working with embedded boards, industrial PCs, or custom controllers, the module adapts instead of forcing a redesign.

In real projects, that flexibility often saves weeks.

2. Performance Parameters That Matter in Real Deployments

Specs still matter — especially when systems scale up. CK-M1LX1 delivers solid, practical performance without chasing unrealistic lab numbers.

Fast, Stable Tag Processing

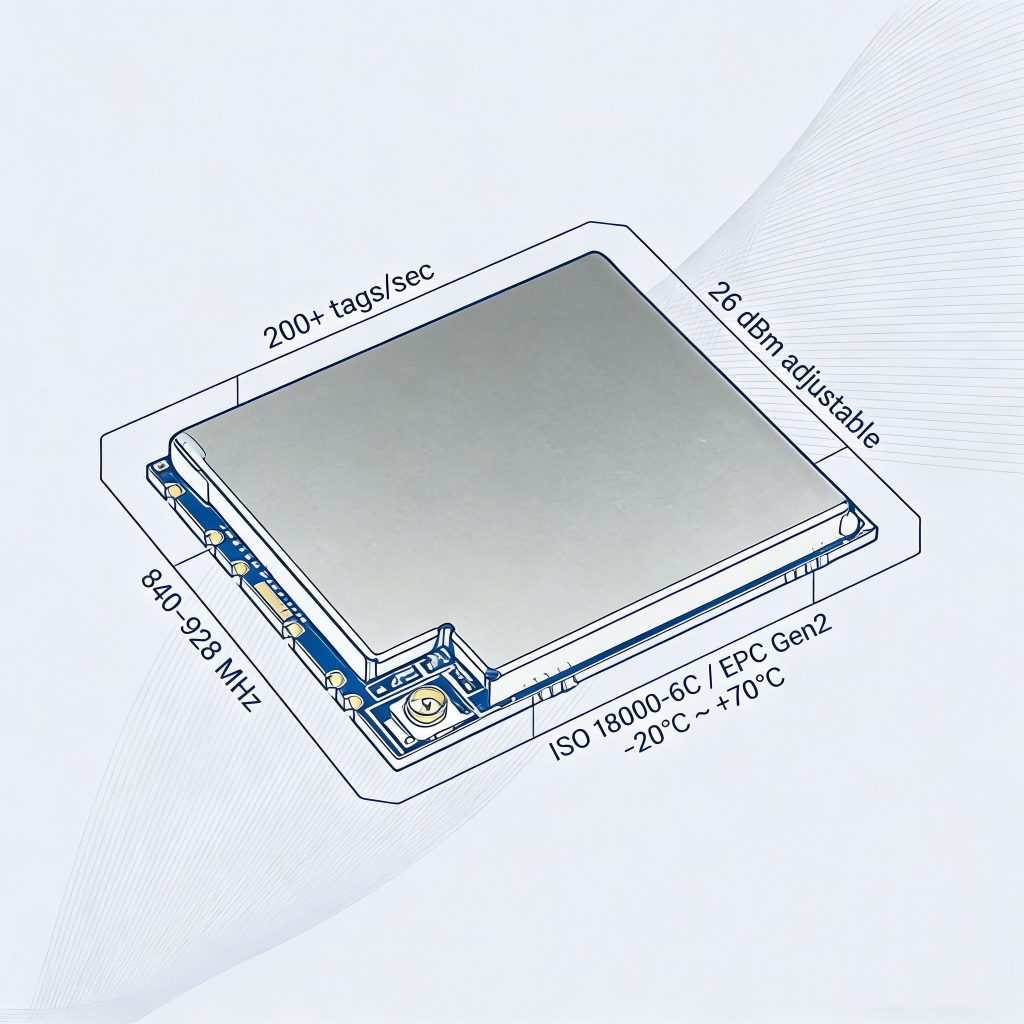

With support for 200+ tags per second, the module performs reliably in dense tag environments. Anti-collision handling is mature enough for real warehouse and production-line scenarios, not just demos.

Global Protocol and Frequency Support

CK-M1LX1 supports:

- ISO 18000-6B / 6C

- EPC Class 1 Gen2

- GB/T29768

- 840–928 MHz, covering FCC, ETSI, and China regions

For hardware buyers and system integrators, this means one module can serve multi-region deployments without swapping SKUs.

Adjustable RF Output Power

With RF output up to 26 dBm ±1 dBm, adjustable via software, teams can fine-tune read distance, interference control, and power consumption. This matters far more in real environments than fixed “maximum power” designs.

Compact, Industrial-Ready Design

The module’s compact footprint, low power consumption (around 2.2W at 26 dBm), and operating range of -20°C to +70°C make it suitable for long-term embedded use — not just short-term pilots.

3. What Hardware Buyers Appreciate

From a procurement and system planning standpoint, CK-M1LX1 checks several important boxes:

- Lower integration risk

Standard APIs and multiple interfaces reduce surprises during system integration. - Shorter deployment cycles

Developers can move faster, which directly impacts project timelines and cost. - Future-proof flexibility

Multi-protocol and multi-region support protect against future expansion needs. - Long-term maintainability

A documented SDK and developer-focused ecosystem reduce dependency on custom firmware work later on.

Final Thoughts

The Cykeo CK-M1LX1 UHF Embedded RFID module isn’t designed just to look good on a datasheet. It’s built for teams that need RFID hardware to behave predictably inside real software systems — while still meeting industrial performance expectations.

For software developers, it feels approachable and structured.

For hardware buyers, it’s stable, flexible, and scalable.

That balance is exactly what most RFID projects need — and often struggle to find.

评论

发表评论