RFID Tags in Industrial Applications:Beyond the Buzz

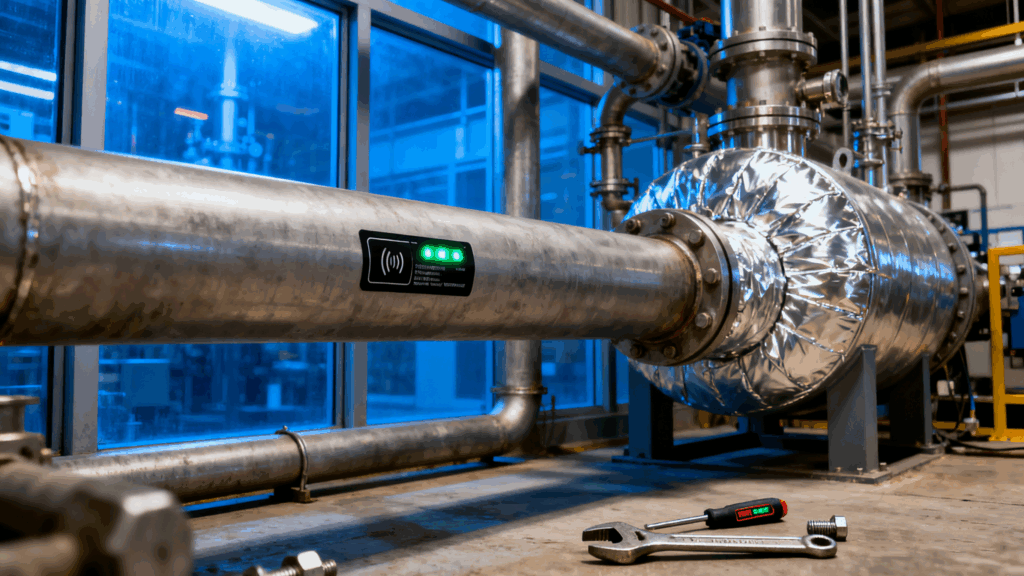

When people talk about rfid tags industrial applications, it’s often described as if RFID is a magic wand that fixes every tracking problem. Reality is, it does solve a lot of headaches — but only if you choose the right tags, frequencies, and don’t underestimate the quirks of your own environment.

In my experience walking factory floors, RFID doesn’t work the same way in a clean warehouse versus a noisy machine shop. You’ll quickly learn that metal racks and water tanks don’t play nicely with certain frequencies. The good part? Once you set it up right, inventory and asset tracking run like a completely different game.

Inventory Management: Where RFID Actually Shines

Most companies start here. Instead of scanning barcodes one by one, you wave an RFID reader and — bam — a whole pallet’s worth of items gets updated in your system. It feels almost too easy the first time you see it.

But there’s a catch. If your tags are cheap paper labels, and you slap them onto metal surfaces, expect read errors. The fix is using “on-metal” tags or adding a small spacer. Not glamorous, but it saves hours of troubleshooting later.

Asset Tracking and Work-in-Process

Heavy tools, test equipment, even forklifts — once they’re tagged, you know who used them last and where they ended up. I’ve seen this reduce tool loss by 30–40% in busy plants.

For production lines, RFID adds a layer of transparency. You can check exactly where a product is in the process without manual logs. This helps reduce bottlenecks and keeps quality audits less of a paperwork nightmare.

Supply Chain and Quality Control

Think beyond the factory. RFID tags travel with shipments, log temperature changes for sensitive goods, or even support recall operations if something goes wrong. When your client calls asking why a batch is delayed, you don’t guess — you show the data.

Practical Notes (a.k.a. the Stuff Nobody Tells You)

- Frequency matters. UHF is great for long-range reading, but struggles around liquids. LF/HF works better near people or dense materials, but read range is shorter.

- Durability counts. If the tags aren’t built for heat, vibration, or chemicals, they’ll fail. Don’t learn this lesson the hard way.

- Integration is half the battle. Tags alone don’t do anything. The real magic comes when your RFID system talks to ERP or WMS software.

Wrapping Up

So, RFID tags in industrial applications are not just a buzzword — they’re a working tool that saves time, reduces errors, and creates data visibility. But like any tool, it’s not about just buying tags and readers. It’s about matching the tech to the messy, imperfect reality of your own factory or warehouse.

评论

发表评论