Boosting Efficiency with Asset Management RFID: Challenges, Lessons, and Action Guide

Introduction

In many organizations, asset management has always been a headache: fixed assets, mobile tools, equipment, inventory… once the volume grows, the types multiply, and the distribution gets scattered, mistakes are bound to happen. Things get misplaced, records go wrong, stock takes consume endless hours.

RFID (Radio Frequency Identification) has been seen as a “rescue tool” here. It allows near real-time or even real-time tracking of asset locations, reduces manual errors, and increases transparency. But in practice, it’s not all smooth sailing. Based on different sources plus my own project experience, here’s a real-world take on asset management RFID.

How RFID Works in Asset Management

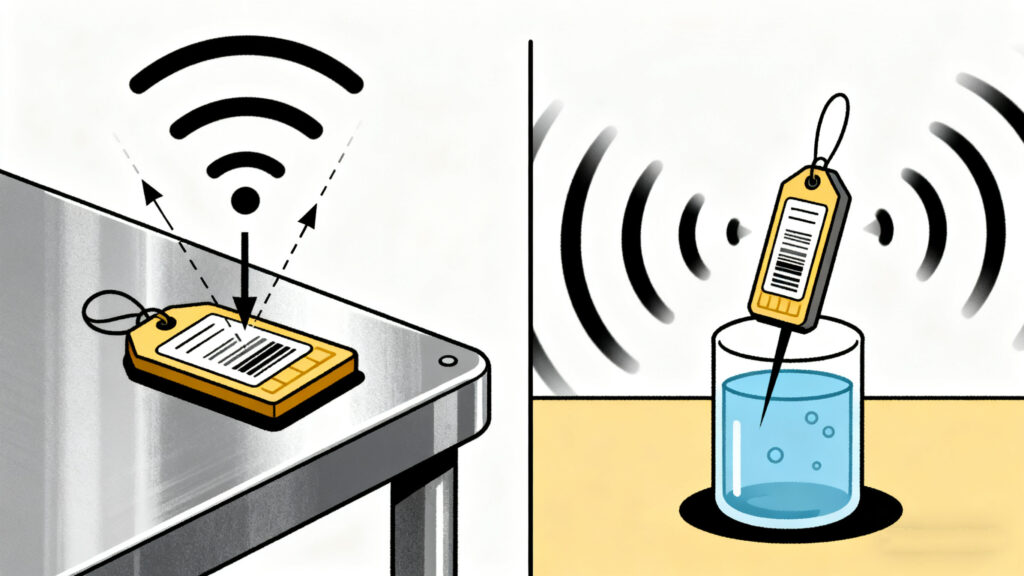

- The basic idea: attach an RFID tag to an asset, then use readers/antennas to pick up the radio signals from those tags. Unlike barcodes, you don’t need direct line of sight.

- Tag types: passive (cheap, short range), active (long range, higher cost, needs battery), and semi-passive.

- What you get: location awareness, movement tracking, status monitoring. Not just “where is it stored,” but also whether it’s in use, under maintenance, or gone missing.

The Advantages

From research plus hands-on work, here are the real perks of using RFID in asset management:

- Huge efficiency boost

No need to scan each asset one by one. In a warehouse project I worked on, switching to RFID cut stocktaking time by around 60%. - Better accuracy, less loss

Manual recording and barcode scanning often result in errors. RFID logs every move, which really helps with returns, reallocations, and tool borrowing. - Real-time or near real-time info

Managers can see where assets are in a building, even set alerts when something is idle for too long or hasn’t been returned. - Fits many industries

Whether manufacturing, hospitals, data centers, or logistics — as long as the tags and readers are chosen properly. It shines when assets are mobile and distributed.

Challenges & Lessons Learned

Rolling out asset management RFID isn’t just plug-and-play. Common headaches and how I (or others) dealt with them:

| Challenge | What happens in real life | Fix / Tip |

|---|---|---|

| High upfront cost | Readers, tags, software, training… the investment scares some companies. | Do ROI analysis. Start with a pilot in one department. Mix active and passive tags depending on need. |

| Environmental interference | Metal and liquids mess up signals, overcrowded areas cause tag collisions. | Do a site survey. Use metal-friendly tags. Adjust antenna placement and power. |

| Integration with existing systems | ERP, inventory software often don’t “talk” well with RFID data. | Plan integration early. Middleware helps convert reader signals into usable data. |

| Tag durability | Regular tags fail outdoors, in heat, moisture, or dusty/chemical environments. | Use industrial-grade tags. Test in real conditions before full rollout. |

| Staff training & process change | People still act like it’s barcodes, misplacing tags or skipping scans. | Train continuously. Write SOPs. Gather feedback during pilot. |

| Privacy & data security | Sensitive equipment or data can be read by unauthorized parties. | Encrypt data. Control access. Store only necessary info on tags. |

Practical Project Takeaways

Some of my personal lessons:

- In a hospital project, we tagged only the high-value, mobile devices first (monitors, portable machines, wheelchairs). Passive tags plus fixed readers at key exits were enough to track movement. Much cheaper than tagging everything.

- Tag placement matters. At first we stuck them to the back of metal casings — terrible idea, signals got blocked. Later moved them to edges or added insulating material, which cut misreads.

- Data filtering is crucial. Sometimes assets showed up in “two places at once” because of overlapping signals. Had to set rules: ignore short blips, use logic to choose the real location.

- Training never stops. If staff don’t change their habits (tag placement, scanning at returns), the system ends up underused, even if the tech works.

Key Steps for Success

If you’re planning an RFID rollout for asset management, I’d suggest:

- Do a site survey first – check walls, metals, humidity, interference.

- Pick the right hardware – tags that survive the environment, readers with proper range.

- Plan system integration – make sure the RFID data flows into your ERP/asset management system.

- Start small – pilot in one area before full rollout.

- Set SOPs – standardize how tags are applied, scanned, and replaced.

- Monitor & improve – regular audits, adjust antennas, keep staff trained.

What If You Don’t Use RFID?

Skipping RFID means:

- Higher labor cost for stocktakes.

- More misplaced/missing assets.

- No real-time visibility for movement.

- Harder compliance with safety and audit requirements.In the long run, even with the upfront cost, RFID usually pays off.

Future Outlook

The direction asset management RFID seems to be heading:

- Cheaper, smaller, smarter tags — even with built-in sensors for temperature, humidity, vibration.

- IoT + AI integration — using RFID data for predictive maintenance and smarter asset allocation.

- Better performance in tough environments — new tag/antenna designs for metal/liquid-heavy sites.

- Stricter security/privacy — encryption and compliance with new regulations.

Conclusion

RFID for asset management is powerful but not flawless. The success lies in:

- Proper planning & site surveys

- Choosing the right tags and readers

- Integrating with existing systems

- Training people and adjusting processes

Don’t just “buy the tech” — build the process around it. That’s the difference between a failed rollout and a system that truly saves time, money, and headaches.

评论

发表评论